LSF structure is one of the most modern building systems that uses cold-rolled light steel and prefabricated panels to provide speed of execution, high quality and design flexibility for residential and commercial projects. This structure has attracted the attention of architects and builders due to its light weight, good earthquake resistance, thermal and acoustic insulation and adaptability to architectural changes. Join us as we introduce LSF structure from 0 to 100.

What is LSF structure?

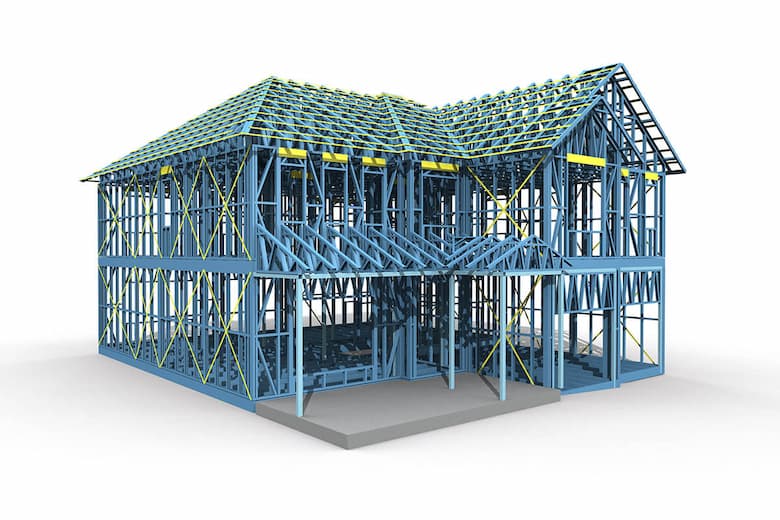

LSF or Light Steel Frame is a modern building system that uses cold-rolled and lightweight steel sections to build the building skeleton. Due to its low weight, high speed of execution and engineering precision, it is widely used in residential, villa, light commercial and even office building projects today. In this system, structural components such as columns, beams and load-bearing walls are prefabricated in the factory and assembled at the project site, which reduces execution errors, saves time and costs and increases the final quality of the building.

In addition to its good resistance to earthquakes due to its low weight and flexible behavior, the LSF structure also has good thermal and acoustic insulation performance and allows for the implementation of diverse architectural designs and easy changes in the plan.

LSF Structure Implementation Guide

In general, LSF structures are known for being much faster and easier to design and implement than traditional structures. Join us as we review the LSF structure implementation guide in 6 stages:

Preparation of drawings and structural design

At this stage, the LSF structure design process begins and includes architectural, structural, and utility drawings. Structural engineers determine the exact specifications of the steel sections, the location of columns, beams, and load-bearing walls, and strength and stiffness calculations are performed based on the building’s dead, live, and lateral loads. This precise design ensures that prefabricated components are produced in accordance with engineering standards and without errors. Coordination between design and implementation, as well as attention to professional construction consulting at this stage, ensures that problems are reduced in the later stages.

Production of prefabricated steel sections

After the drawings are approved, light steel sections are produced in the factory using galvanized sheets. These components include columns, beams, frames, and wall profiles, and are cut, punched, and bent to precise specifications. Industrial production increases accuracy, consistent quality, and reduces material waste, significantly speeding up project execution on site.

Foundation and substructure preparation

Before assembling the frame, the building foundation must be ready and strong. This stage includes preparing the ground, leveling, and constructing concrete footings that will support the weight of the LSF structure. Given the lightness of the structure, the foundation can support less load than heavy concrete and metal structures, but precision in its execution is very important to prevent settlements, cracks, or misalignment of the frame.

Steel frame assembly

In this stage, steel columns and beams are installed on the foundation according to the drawing and connected to each other with bolts and nuts or welding. The frames are assembled in stages, observing perfect levelness and alignment. Careful attention to detail at this stage increases the strength of the building, its resistance to earthquakes, and its longevity. The installed frame also provides a suitable base for installing the walls and roof.

Installing the walls, floor, and roof

After the frame is completed, lightweight wall, floor, and roof panels are installed. These panels usually have a thermal and acoustic insulation layer and are easily placed on the frame and secured with screws or fasteners. Proper installation of the panels, in addition to increasing the strength of the structure, improves the building’s energy efficiency, reduces sound transmission, and creates a comfortable and safe environment.

Finishing and interior installations

Finally, in the final stage, the building’s finishing work includes interior and exterior coatings, painting, installation of doors and windows, and flooring. Electrical, mechanical, plumbing, and heating and cooling systems are also installed. This stage prepares the building for occupancy and ensures that all structural components and internal facilities are coordinated and implemented to standard.

Advantages of LSF structure

Using LSF structure in construction projects can bring numerous advantages in terms of costs, time, implementation process, and also flexibility in design. Join us to fully introduce the advantages of LSF structure:

High speed of implementation and reduced construction time

One of the most important advantages of LSF structure is its very high speed of implementation compared to traditional buildings. By using prefabricated steel parts and rapid assembly of the skeleton on site, the construction process can be shortened by several months. This feature is a great advantage, especially for residential, commercial, and villa projects that require quick delivery.

Light weight and reduced pressure on the foundation

Like Kit House, LSF structure has much less weight than traditional concrete and steel structures due to the use of cold-rolled light steel and prefabricated panels. This feature causes less pressure to be applied to the foundation and allows the use of simpler and more economical foundations. Reducing the weight of the structure also increases the desired performance against earthquakes and minimizes the risk of settlements and cracks in the building.

High resistance to earthquakes and lateral forces

Due to the low weight and flexibility of light steel, the LSF structure is able to withstand lateral forces caused by earthquakes and strong winds. Bolted connections and precise design of the frames allow the energy caused by vibrations to be distributed evenly in the structure and the risk of failure is reduced. This feature has made the LSF structure one of the safe and resistant options in earthquake-prone areas and provides reassurance to residents and investors.

Improved thermal and acoustic insulation

Another advantage of the LSF structure is the ability to easily install thermal and acoustic insulation in walls, floors and ceilings. Prefabricated panels can include high-quality insulation layers that reduce energy consumption for heating and cooling the building. In addition, the installation of these insulations reduces sound penetration and creates a quiet and comfortable environment for residents. Therefore, the LSF structure, in addition to being strong, also creates a cost-effective and energy-friendly environment.

Flexibility in design and architectural changes

The LSF structure allows designers and architects to easily make changes to the plan and facade. The lightweight structure and prefabricated components make it possible to add or remove walls, create openings and change the interior decoration design without destroying the structure. This flexibility allows LSF buildings to meet the different needs of residential and commercial projects, while at the same time implementing the building facade and interior design with greater precision and beauty.

Who is the LSF structure suitable for?

- People looking for a quick construction of a building

- People who want to reduce construction and foundation costs

- Residents living in earthquake-prone areas

- People interested in modern and flexible architectural design

- People who want a building with proper thermal and acoustic insulation

- Investors who need a quick project delivery

- People who care about the lightness of the structure and reducing the load on the ground

Final Words

As you can see, in this article, we have fully introduced the LSF structure. We have learned that the LSF structure, with its features such as high speed of implementation, light weight, resistance to lateral forces, etc., is an ideal option for people looking for modern, safe and economical buildings. By following the correct implementation steps and using standard prefabricated parts, this type of structure can provide a safe and low-cost experience for residents and investors. Thank you for your support.